Brochures

Our approach is distinctly innovative. We constantly seek new ways to increase client

Our approach is distinctly innovative. We constantly seek new ways to increase client

Shree Balaji Detchem is a trusted manufacturer and exporter of Toilet Soap Plants designed for high-quality soap production with precision and reliability.

We are well-experienced in designing and delivering state-of-the-art toilet soap manufacturing facilities that meet international standards. Our expert team ensures each plant is built with advanced technology and reliable project management, providing turnkey solutions tailored to client needs and budgets.

We manufacture Toilet Soap Plants with production capacities ranging from 300 Kgs/hr to 3000 Kgs/hr, ensuring flexibility and scalability for both small and large-scale manufacturers.

Mechanical engineering is the discipline that applies engineering, physics, engineering mathematics, and materials science principles to design, analyze, manufacture, and maintain mechanical systems. It is one of the oldest and broadest of the engineering disciplines.

The Sigma Mixer is the first stage of the soap-making process. It is designed to mix raw materials such as soap noodles, additives, and colors into a uniform, homogenous mass. The robust double-arm design ensures thorough blending and consistent texture in every batch.

After mixing, the material passes through the Refiner/Noodler, which refines the soap mixture into smaller, more uniform noodles. This process enhances smoothness and improves the final product quality by removing impurities and large particles.

The Triple Roll Mill is used to achieve an even finer texture by pressing the soap mass between three precision rollers. This ensures perfect consistency and a silky finish for premium toilet soaps. The machine’s high efficiency minimizes wastage and maximizes output.

Finally, the Soap Stamper shapes the extruded soap into desired bar forms. The machine provides accurate stamping with logos or brand impressions, ensuring your final soap bars have a professional and appealing finish.

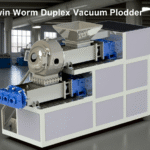

The Twin Worm Duplex Vacuum Plodder compacts, refines, and extrudes the soap under vacuum, removing air pockets to produce dense and smooth soap bars. Its twin-worm design guarantees uniform extrusion and enhances bar strength and shine

Custom-built plants to match your production scale

Durable machinery built with precision engineering

Turnkey project handling – from design to installation

After-sales support and training

📍 Address: 143/144, Kamal Estate, Nr. Bombay Conductor, Vatva GIDC, Ahmedabad – 382445

🌐 Website: www.shreebalajidetchem.com

📧 Email: info@shreebalajidetchem.com

📞 Phone: +91 97256 05639