Looking for a small scale detergent cake making plant in India? Discover cost, machines, setup process, and why Shree Balaji Detchem is the best detergent cake plant manufacturer in India.

🏭 Shree Balaji Detchem

The small scale detergent cake making plant is one of the most profitable manufacturing setups in India today. With rising demand for cleaning products, small entrepreneurs and detergent manufacturers are looking for cost-effective, automatic, and efficient detergent cake production lines.

At Shree Balaji Detchem, we provide turnkey solutions for detergent cake plants — from mixing to stamping — with advanced machinery such as the Sigma Mixer, Multi Screw Conveyor, Vacuum Plodder, Long Bar Cutter, and Auto Stamper. Whether you’re planning a small business setup or upgrading to a fully automatic detergent cake plant, this guide will help you understand the setup, cost, and complete manufacturing process.

🔹 What is a Small Scale Detergent Cake Making Plant?

A small scale detergent cake plant is a compact setup designed to manufacture detergent bars or cakes using automatic and semi-automatic machines. The plant includes equipment for mixing raw materials, conveying, extrusion, cutting, and stamping.Small Scale Detergent Cake Making Plant

Such setups are perfect for:

- Entrepreneurs starting a detergent business.Small Scale Detergent Cake Making Plant

- Medium-scale manufacturers expanding production.

- Custom or contract manufacturers.

These plants are affordable, space-efficient, and can produce 100–500 kg/hr depending on configuration.

🧰 Machine Overview – Key Equipment Used in Detergent Cake Manufacturing

The efficiency and quality of detergent cake production depend on the machinery used. A small scale detergent cake plant includes a series of advanced machines that work together for consistent production, minimal wastage, and high output.best for Small Scale Detergent Cake Making Plant

Here’s a detailed overview of each machine used in the process:-

🌀 1. Sigma Mixer – The Heart of the Process

Small Scale Detergent Cake Making Plant Sigma mixer is the 1st Machine The Sigma Mixer is the most crucial machine in the detergent cake manufacturing plant.

It blends various raw materials such as acid slurry, soda ash, sodium silicate, and fillers into a homogeneous paste.Small Scale Detergent Cake Making Plant

Key Highlights:

- Heavy-duty double arm blades for uniform mixing.

- Made of high-grade stainless steel for corrosion resistance.

- Ensures perfect blending consistency.

- Available in multiple capacities (100 to 500 kg/hr).

Purpose: Small Scale Detergent Cake Making Plant

To achieve a smooth, uniform detergent base — ensuring better performance of the final detergent cake.

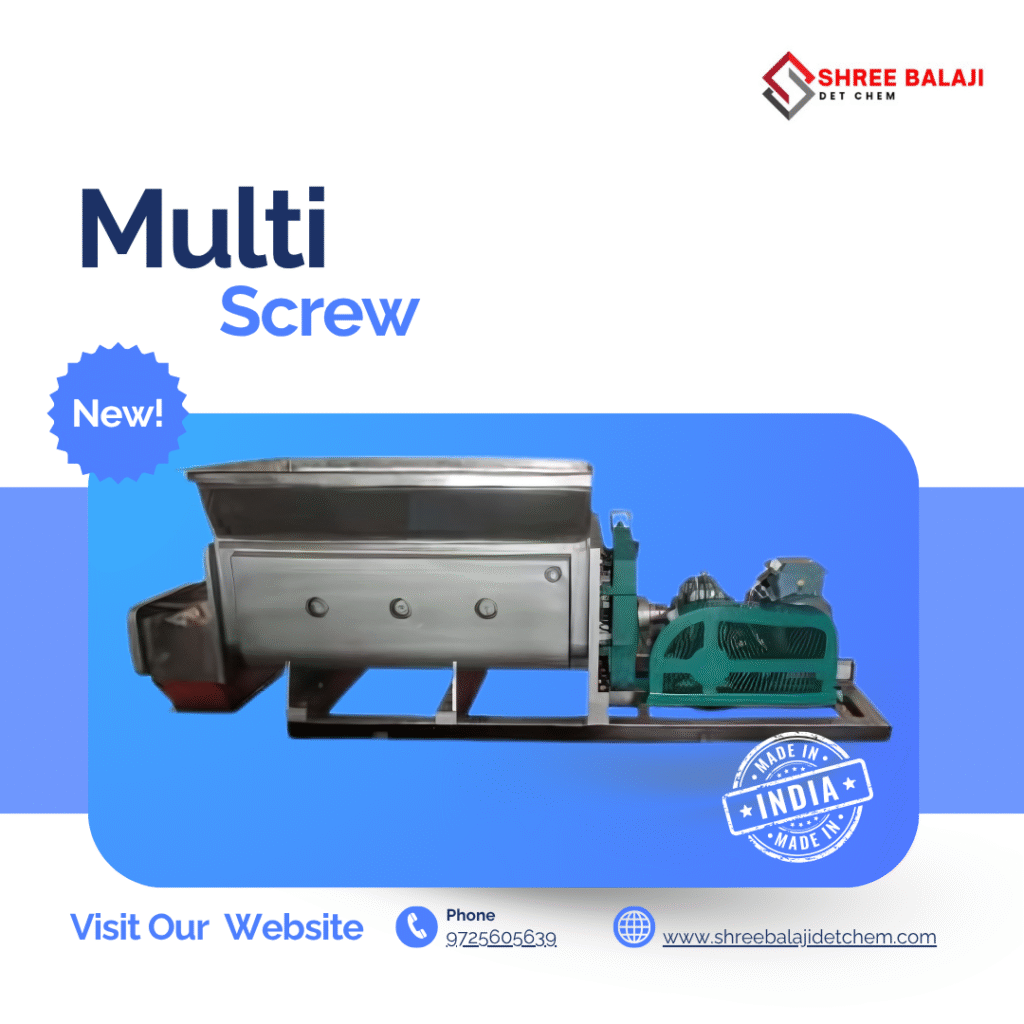

🔁 2. Multi Screw Conveyor – Small Scale Detergent Cake Making Plant

Once the material is mixed, it needs to be transferred safely and efficiently to the next process.

The Multi Screw Conveyor automatically conveys the detergent mass from the Sigma Mixer to the Vacuum Plodder.

Key Highlights:

- Compact design with variable speed control.

- Eliminates manual handling and contamination.

- Ensures continuous flow for uninterrupted production.

Purpose:

To provide a clean and efficient method of transferring material while reducing labor costs.

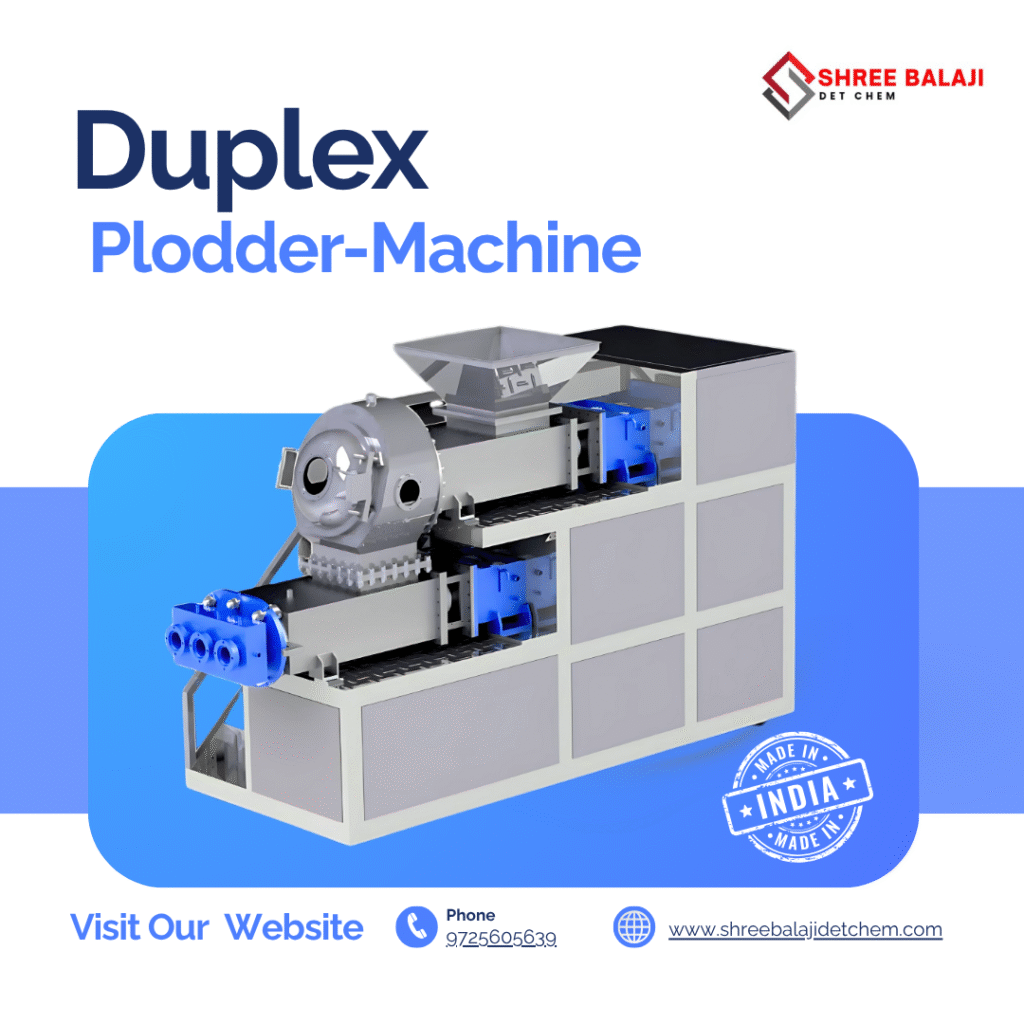

🧱 3. Duplex Plodder – Extrusion & Densification

The Duplex Plodder plays a key role in shaping the detergent mixture into bars.

It compresses and extrudes the detergent paste under vacuum conditions, removing air bubbles and ensuring a solid, dense output.

Key Highlights:

- Dual-stage extrusion system.

- High vacuum chamber for bubble-free cakes.

- Adjustable nozzle for bar size customization.

- Easy maintenance and long service life.

Purpose:

To give detergent cakes their shape, density, and smooth texture — ready for cutting.

✂️ 4. Long Bar Cutter – Precision Cutting System

The extruded detergent bar from the Vacuum Plodder is passed through the Long Bar Cutter, which slices it into smaller cakes of uniform size.

Key Highlights:

- Stainless steel cutting blades.

- Adjustable cutting length.

- Simple and fast operation.

- Consistent dimensions every time.

Purpose:

To ensure each detergent cake is evenly cut, maintaining product quality and professional appearance.

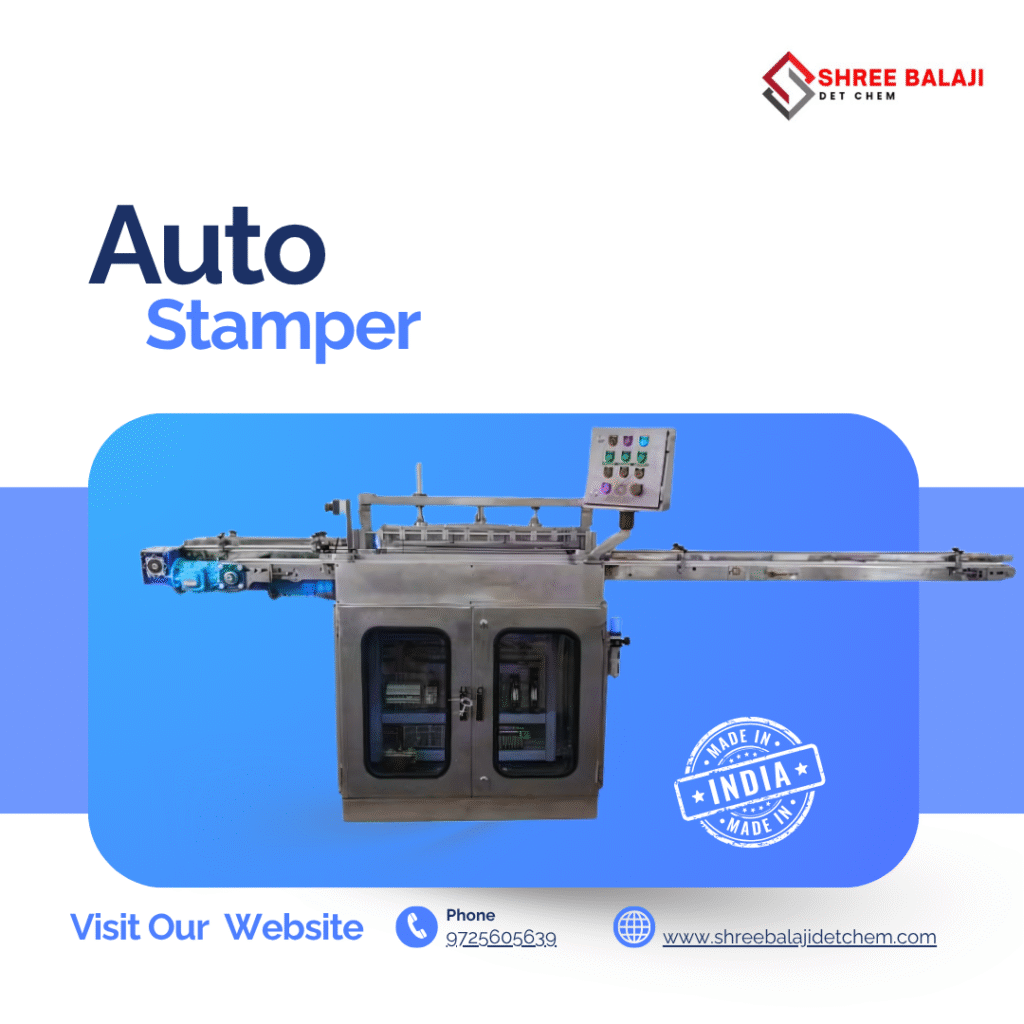

🔖 5. Auto Stamper – Branding and Final Touch

The Auto Stamper gives the final product its professional, branded look.

It stamps company logos or product names on each detergent cake, improving aesthetics and brand recognition.

Key Highlights:

- Pneumatic operation for high-speed stamping.

- Consistent logo impression with smooth finish.

- Compatible with multiple stamp designs.

- Easy mold change system for different products.

Purpose:

To make your detergent cakes look professional, attractive, and market-ready with a lasting brand identity.

⚙️ Machine Integration Overview

All these machines — the Sigma Mixer, Multi Screw Conveyor, Vacuum Plodder, Long Bar Cutter, and Auto Stamper — are interconnected in a streamlined production line.

The workflow is designed to minimize human intervention, optimize energy usage, and maximize productivity.

When installed as a turnkey detergent cake plant, this setup provides:

- Continuous production line with minimal downtime.

- Low maintenance cost.

- Easy scalability from 100 kg/hr to 500 kg/hr.

✅ Summary Table – Machine Overview

| Machine | Function | Key Benefit |

|---|---|---|

| Sigma Mixer | Mixing raw ingredients | Uniform detergent base, consistent texture |

| Multi Screw Conveyor | Material transfer | No contamination, continuous operation |

| Vacuum Plodder | Extrusion and compression | Bubble-free, dense detergent bars |

| Long Bar Cutter | Cutting detergent bars | Uniform product size, smooth edges |

| Auto Stamper | Branding and stamping | Professional finish and product identity |

Best for New Startup Small Scale Detergent Cake Making Plant 2025

⚙️ Complete Machine List and Specifications

Below is a list of essential machines used in a small scale detergent cake making plant by Shree Balaji Detchem:

| Machine Name | Function | Capacity | Power Requirement | Key Features |

|---|---|---|---|---|

| Sigma Mixer | Mixing detergent raw materials into a uniform paste | 100–500 kg/hr | 5–15 HP | Heavy-duty double-arm design, stainless steel body, efficient mixing |

| Multi Screw Conveyor | Transfers mixed material to next stage | 100–500 kg/hr | 2–3 HP | Rust-proof screw design, smooth feeding, minimal wastage |

| Vacuum Plodder | Extrudes and compresses the detergent mass into solid bars | 100–500 kg/hr | 7–10 HP | Dual stage extrusion, vacuum chamber for bubble-free cakes |

| Long Bar Cutter | Cuts long detergent bars into uniform pieces | Adjustable | 1–2 HP | Stainless steel blades, precision cutting, easy operation |

| Auto Stamper | Stamps brand logo or pattern on detergent cakes | 10–60 strokes/min | 1–2 HP | Fully automatic, pneumatic system, consistent finish |

🧪 Step-by-Step Manufacturing Process

Small Scale Detergent Cake Making Plant 2025

1. Raw Material Preparation

Detergent cake formulation includes acid slurry, soda ash, sodium silicate, perfume, color, and fillers. All ingredients are pre-measured and ready for mixing.

2. Mixing in Sigma Mixer

The Sigma Mixer blends raw materials into a uniform semi-solid paste. It ensures perfect consistency and eliminates lumps — the key to high-quality detergent cakes.

3. Conveying through Multi Screw Conveyor

After mixing, material is automatically conveyed to the Vacuum Plodder using a multi screw conveyor, minimizing manual handling and contamination.

4. Extrusion in Vacuum Plodder

The Vacuum Plodder extrudes the mixture into a continuous bar while removing air bubbles. The result is a dense, smooth, and long detergent bar ready for cutting.

5. Cutting with Long Bar Cutter

The extruded bar passes through the Long Bar Cutter, which slices it into desired lengths with uniform dimensions.

6. Branding using Auto Stamper

Each cut piece is stamped using the Auto Stamper, giving it a professional branded look. You can customize the stamp with your logo or product name.

7. Packaging

The finished detergent cakes are naturally or via a small packed in printed wrappers or shrink films for sale.Small Scale Detergent Cake Making Plant 2025

💰 Detergent Cake Making Plant Cost in India

The cost of a small scale detergent cake making plant in India depends on production capacity and automation level:

| Plant Type | Capacity | Approx. Cost Range (INR) |

|---|---|---|

| Manual / Semi-Automatic | 100–300 kg/hr | Request for price |

| Fully Automatic Plant | 500 kg/hr | Request for price |

| Customized plant (Installation + Training) | Customized plant | Request for price |

💡 Prices vary depending on material quality, motor specifications, and level of automation.Small Scale Detergent Cake Making Plant 2025

🧰 Space, Power, and Setup Requirements

- Space Required: 800–1500 sq. ft. (for small scale plant)

- Power Load: 15–25 HP depending on machines

- Manpower: 3–5 skilled workers

- Water Requirement: Minimal

- Production Capacity: Up to 500 kg/hr

⚡ Features of Shree Balaji Detchem Detergent Cake Plants

✅ Heavy-Duty Construction

✅ Stainless Steel Contact Parts

✅ Low Maintenance and Long Life

✅ Compact Design Suitable for Small Scale Units

✅ Easy Installation & Operation

✅ High Output with Minimum Labor

✅ Available in Manual, Semi-Automatic, and Fully Automatic Models

🏗️ Complete Detergent Cake Plant Setup Cost and Installation

At Shree Balaji Detchem, we offer turnkey detergent cake plant projects across India. Our experts handle:Small Scale Detergent Cake Making Plant 2025

- Site inspection and layout planning

- Machine installation and alignment

- Electrical & mechanical setup

- Operator training

- Trial production run

- After-sales service and maintenance

We ensure smooth commissioning so you can start production without delay.

🧩 Automatic Detergent Cake Plant with Vacuum Plodder & Stamping System

Our fully automatic detergent cake plant integrates:

- Sigma Mixer for batch mixing

- Vacuum Plodder System for bubble-free extrusion

- Long Bar Cutter for precision cutting

- Auto Stamping Machine for consistent branding

This setup is ideal for bulk manufacturers who want maximum efficiency and consistent quality.

🧍♂️ Why Choose Shree Balaji Detchem?

Founded in 2017, Shree Balaji Detchem has become one of the best detergent cake plant manufacturers in India. We specialize in designing, fabricating, and exporting detergent cake and powder making machinery.

Key Advantages:

- Experienced team of engineers and technicians

- Customized solutions for small and large businesses

- High-performance machines with low power consumption

- Quick installation and training support

- Affordable pricing and nationwide delivery

We are trusted detergent cake plant machinery manufacturers and suppliers in India with clients across Gujarat, Maharashtra, Rajasthan, and beyond.

🔍 Additional Services

- Used detergent cake plant for sale (Refurbished options available)

- 500 kg/hr detergent cake plant machine price consultation

- Complete plant setup cost estimation

- Detergent cake plant installation and training services

❓ Frequently Asked Questions (FAQs)

1. What is the cost of setting up a small scale detergent cake plant in India?

A small scale plant costs around ₹4.5–₹7 Lakhs depending on capacity and automation level.

2. Which machines are required for a detergent cake manufacturing unit?

You need a Sigma Mixer, Multi Screw Conveyor, Vacuum Plodder, Long Bar Cutter, and Auto Stamper.

3. What is the production capacity of a small detergent cake plant?

Typically ranges from 100–500 kg/hr depending on machine configuration.

4. Can I get installation and operator training support?

Yes. Shree Balaji Detchem provides full installation, training, and maintenance support.

5. Do you supply fully automatic detergent cake plants?

Yes, we design fully automatic detergent cake plants with vacuum plodder and auto stamping systems.

🏁 Conclusion

Starting a small scale detergent cake making plant in India is a profitable venture with high market demand and low investment. With the right setup and machinery, you can manufacture high-quality detergent cakes efficiently.

Choose Shree Balaji Detchem — the best detergent cake plant manufacturer in India — for reliable machinery, expert support, and complete turnkey project solutions.

Starting a small scale detergent cake making plant is not just a great business idea — it’s a growing opportunity in the home care industry. With minimal investment and the right set of machines, you can easily set up a production line that delivers high-quality detergent cakes at affordable prices.

If you’re planning to enter this industry, make sure to understand the formulation process, mixing ratios, and machine types such as Sigma Mixer, Triple Roll Mill, and Plodder Machine. Reliable suppliers like Shree Balaji Detchem offer complete detergent cake manufacturing setups, including installation and training support.

By following standard guidelines and maintaining consistent product quality, your brand can compete with established detergent manufacturers in the market. You can also explore government initiatives and MSME schemes that support small manufacturing businesses in India.

For additional resources on detergent formulations and small manufacturing guidance, visit Entrepreneur India or MSME India.

With the right planning, technical knowledge, and quality assurance, a small detergent cake making plant can become a profitable and sustainable business venture for years to come.

📞 Contact Shree Balaji Detchem

Looking to start your own small scale detergent cake making plant or want to know the complete setup cost and machine details? Our team of experts is here to guide you through every step — from machine selection to installation and operator training.

📍 Office Address:

143/144, KAMAL ESTATE, NR. BOMBAY CONDUCTOR, VATVA GIDC, AHMEDABAD – 382445

📞 Phone: +91 97256 05639

🌐 Website: www.Shreebalajidetchem.com

✉️ Email: Info@shreebalajidetchemgmail.com

💬 Get in touch with Shree Balaji Detchem today for your custom detergent cake plant setup and start your manufacturing journey with trusted industry experts.